Company news

How Fiver Ensure Heat Dissipation and Safety in Our CCS Charging Cables

Ensuring Heat Dissipation and Safety in Our CCS Charging Cables for EV Fast Charging

As a professional manufacturer specializing in high-quality CCS charging cables for Electric Vehicles, we are committed to meeting the strictest technical requirements to ensure both efficient heat dissipation and utmost EV charging safety. Our products are designed with a meticulous approach, taking into account various aspects from material selection to performance testing. We understand the critical role of our EV charging cablesin enabling reliable and safe EV fast charging, especially with the increasing demand for high power charging and HPC charging. This commitment to quality and safety extends to every component, including the integration of highly accurate PT1000 temperature sensors.

Stringent Technical Requirements: The Foundation of Quality

Our CCS charging cables adhere to the highest industry standards, exceeding typical requirements in several key areas:

-

Terminal Pull-Out Force: We enforce strict pull-out force standards tailored to different wire cross-sectional areas. This ensures a robust connection between terminals and wires, preventing accidental disconnections during charging, a critical EV charging safety concern. (for our 1000V DC 375A Air Cooled CCS2 Charging Cables e.g., 80N for 0.75mm², up to 2700N for 100mm²).

-

Charging Plug/Housing Material: Our plug housings utilize PC/PA66, a high-performance alloy. This material combines the impact resistance and dimensional stability of polycarbonate (PC) with the strength, stiffness, and heat resistance of polyamide 66 (PA66). This ensures a durable, protective housing that also contributes to thermal management.

-

Conductor Material: We employ Silver plating over nickel with a copper base conductors. Copper provides excellent conductivity and con-structure strength; A intermediate nickel plating layer with a thickness of 5-10 μm blocks the diffusion of copper and silver, prevents the increase in contact resistance caused by "copper migration", and at the same time enhances wear resistance and corrosion resistance; The silver plating layer thickness is 5-8μm. Utilizing the ultra-high conductivity of silver (conductivity of 105% IACS) reduces the contact resistance to below 0.5mΩ, and an Ag₂O oxide film is formed on the surface to inhibit further oxidation.ensuring long-term performance and EV charging safety.

-

Cable Standard: Our EV charging cables comply with the IEC 62893 standard, guaranteeing high quality, reliability, and compatibility with a wide range of Electric Vehicles.

-

Conduction Correctness: We guarantee 100% conduction correctness with zero error pole phenomenon. This is paramount for safe operation, preventing incorrect electrical connections that could damage the vehicle or charging equipment.

-

Product Quality: Rigorous quality control ensures our CCS charging cables are free from defects such as scratches, cable damage, dirt, heat shrink tubing issues, and terminal detachment.

Design and Performance: Optimizing for Heat Dissipation and Safety in High Power Charging

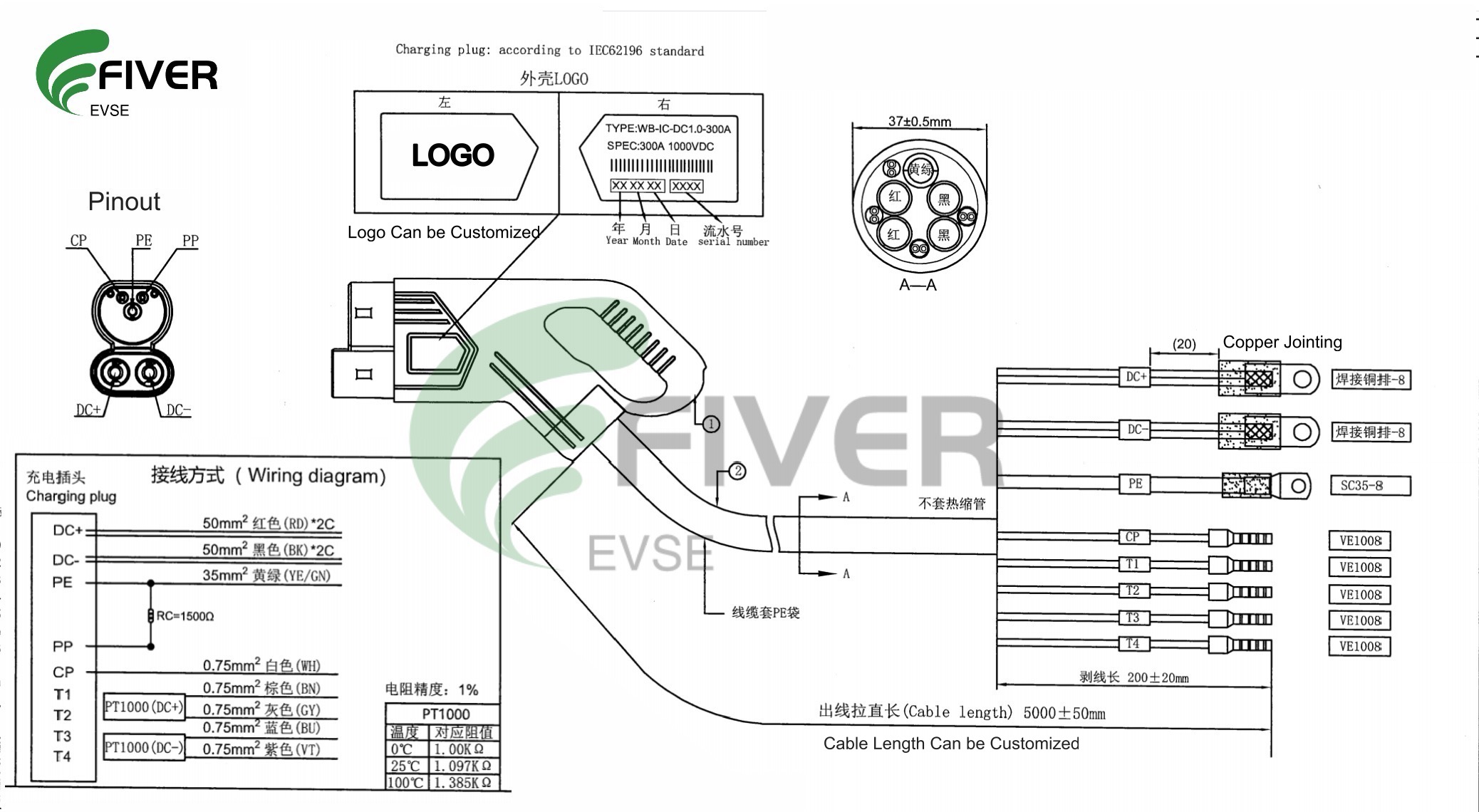

1000V DC 300/350A CCS2 Charging Cable Air Cooled

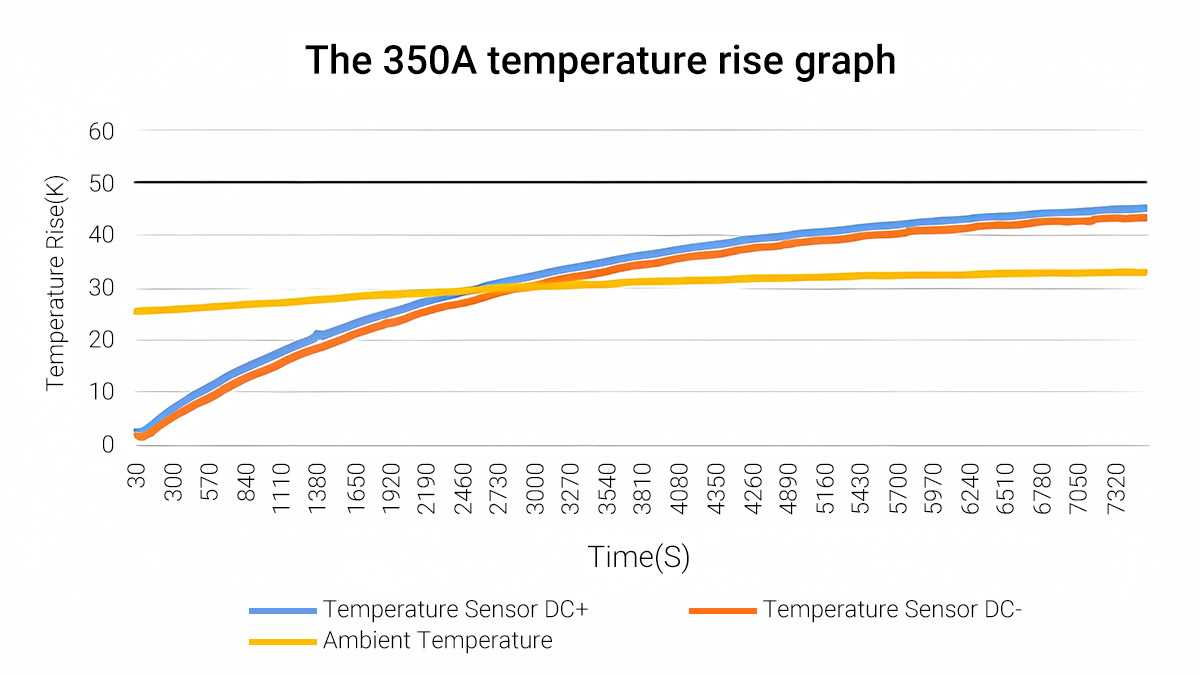

Our innovative cable design often utilizes two thinner cables in parallel instead of a single thick cable, especially in high power charging applications (e.g., 1000V 350A or 375A). This approach offers significant advantages in heat dissipation and safety, based on the principle of current-carrying capacity superposition of parallel conductors (per IEC 60287).This is particularly important for HPC charging where heat generation is a significant concern. Furthermore, the integration of PT1000 temperature sensors provides highly accurate temperature monitoring, a crucial element for safe and efficient high-power charging.

Key Advantages of Our Dual-Cable Design for EV Fast Charging:

-

Enhanced Heat Dissipation:

- Increased Surface Area/Volume Ratio: Parallel cables offer a significantly larger surface area for heat dissipation compared to a single thicker cable, leading to a 41% improvement in heat transfer.

- Uniform Thermal Distribution: Distributing the current across two conductors minimizes localized temperature increases and prevents hot spots, crucial for EV charging safety. This is further enhanced by the precise temperature readings provided by the integrated PT1000 sensors, allowing for real-time thermal management.

-

Improved Flexibility and Mechanical Properties:

- Reduced Bending Radius: Thinner cables offer a smaller bending radius, making them ideal for applications with frequent movement, such as charging gun cables.

- Enhanced Fatigue Resistance: The stranded structure of multiple thin wires improves fatigue resistance, allowing the cable to withstand repeated bending without failure.

-

Redundant Safety Design: Parallel conductors provide a built-in safety redundancy. If one conductor is partially damaged, the remaining conductor can still carry a significant portion of the current, minimizing the risk of failure and enhancing EV charging safety. Combined with the accurate temperature monitoring of the PT1000 sensors, this redundancy system provides an extra layer of protection.

-

Balanced Cost and Weight: While using more copper, the dual-cable design allows for optimized insulation, potentially leading to cost savings. Additionally, the option to use lighter materials like high-purity copper or copper-clad aluminum further reduces weight, aligning with the lightweighting trend in Electric Vehicles.

| Parameter | Single Strand of 70 mm² | Parallel Connection of Two 50 mm² Cables |

| Cross-sectional Area | 70 mm² | 100 mm² |

| Current-carrying Capacity (in an Environment of 30℃) | 250A | 350A |

| DC Resistance (at 20℃) | 0.268 Ω/km | 0.176 Ω/km |

| Power Loss (at 350A) | I2R=2502*0.268=16.75W/M | I2R=3502*0.176/2=10.78W/M |

| Temperature Rise (ΔT) | 45K (Measured Value) | 32K (Measured Value) |

Engineering Considerations for Reliable EV Charging:

- Connector Design: Precise matching of dual cables with low-resistance terminals (e.g., silver-plated copper alloy) is crucial for even current distribution.

- Electromagnetic Compatibility (EMC): We utilize twisted pair or shielding structures to mitigate potential electromagnetic interference, adhering to CISPR 25 standards.

- Standardization Compatibility: Our EV charging cables comply with relevant industry standards (e.g., GB/T 20234-2015) for compatibility with a wide range of Electric Vehicles.

Real-World Validation of High Power Charging Solutions:

The effectiveness of our design is validated by real-world examples, such as the Tesla V3 Supercharger, which utilizes a similar multi-strand parallel cable design. This approach has demonstrated significant reductions in temperature rise and cable weight.

Conclusion:

Our CCS charging cables are meticulously engineered to deliver superior heat dissipation, safety, and performance for EV fast charging, including high power charging and HPC charging. The innovative dual-cable design, combined with stringent quality control, adherence to industry standards, and the integration of highly accurate PT1000 temperature sensors, positions us at the forefront of EV charging technology. As the industry advances, particularly with the rise of 800V platforms and higher charging powers, we are confident that our multi-conductor parallel cable design will become the mainstream solution for high-voltage, high-current cables. We are committed to continuous innovation to meet the evolving needs of the EV charging market and provide our customers with the most advanced and reliable charging solutions.

Categories

Latest News

Contact Us

Contact: Jerry Zhan

Phone: WhatsApp: +8618028699987

Tel: +86-023-20791348

Add: No.2201,AESC Center, Yubei District Chongqing China